STOUGHTON, WI

ZINKPOWER is one of the world’s leading hot-dip galvanizing groups operating 50 facilities in 13 countries across Europe, the America’s, and Asia. Hot-dip galvanizing applies a zinc coating to steel, making it an ideal building material that offers lasting corrosion protection. In a moderate atmosphere, galvanized steel can last over 50 years and requires little to no maintenance. Morse Electric is completing this Design Build project in partnership with Winter Construction and have been on site since November 2020. The first ceremonial dip took place on December 16, 2021.

MAINTENANCE BUILDING

The 8,325 sq. ft. maintenance building was the first structure to go up on the ZINKPOWER site. It features climate controlled equipment storage, completed office space, large meeting room, IDF and electrical rooms. Electrical service to the maintenance building is feed from the manufacturing facility. Since the maintenance building was completed prior to the construction of the manufacturing facility, Morse Electricians utilized a temporary power skid located near the future site for the main electrical room to provide service from the utility company to the maintenance building. 1,020’ of underground cable was installed to bridge the distance between the two buildings.

Maintenance Building Office Space

Garage Doors

Wooden Trusses and Plywood Roof

MANUFACTURING FACILITY

The ZINKPOWER manufacturing facility has some features that you don’t see everyday in this type of building. For starters, the building is not insulated or conditioned like a traditional building. The heat generated by the zinc kettle will be enough to keep the building warm in the winter. The owner also elected to install wooden trusses and a plywood roof on the facility. Another unique feature are the seven, aviation style garage doors that span the south and west sides of the building. Morse Electricians installed the conduit and cable to power the eyes and push buttons that operate the doors. To date, crews have completed the installation of the building systems, power, and fire alarm and work on the process power is nearing completion. Next, crews will begin installing the fiber, low-voltage CAT 6 communication system, WAP’s, CCTV security, and card access.

MSB2 Feeder Trench

UNDERGROUND

A large portion of the electrical installation at ZINKPOWER consisted of digging trenches and installing underground conduit. The outdoor lighting circuit alone spans over 3,000’. In total, crews installed over 25,000’ of underground conduit for this project.

Cable Tray Installation

CABLE TRAY

Morse Electricians installed over 1,800’ of cable tray throughout the facility to support the process power, control, and signal wiring from the control room. Crews also installed over 53,000’ of process cabling.

Temporary Main Breaker in the Main Electrical Room

ELECTRICAL ROOM

Securing equipment and material has become increasingly challenging, and this project was no exception. The Morse team came up with creative solutions to keep the project moving forward. In the electrical room, crews installed a temporary main breaker that would allow for work to proceed while they wait for the delayed automatic transfer switch (ATS) to arrive. Once the facility is operational, it will take three weeks to heat the zinc from ambient temperature to the liquid temp required for the hot-dip galvanizing process. It’s imperative to maintain this consistent temperature once it’s been reached. The ATS will be used to transfer power to the backup generator in the case of a power outage.

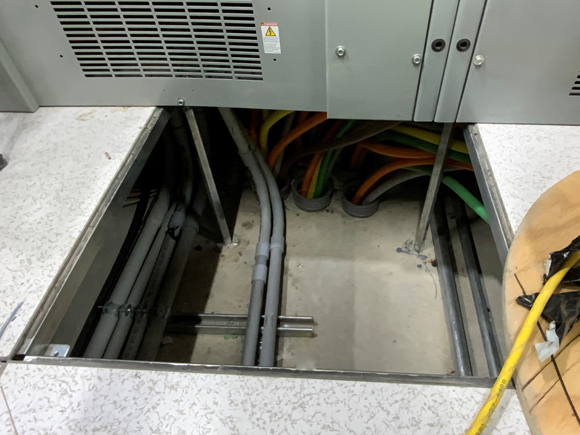

All Control Room Cabling Installed in Cable Tray Under the Floor

Parallel Feeders From the Main Electrical Room Switchgear to the Control Room Switchgear

CONTROL ROOM

The control room for ZINKPOWER contains a second fully rated switchboard that feeds and controls the hot-dip galvanizing process. The switchboard rests on a depressed slab and is feed from the main switchboard with seven underground parallel sets of 750 Stabeloy aluminum cable. A raised computer floor allows for power and process cables to be installed in cable tray that runs beneath the floor and feeds the process control panels from the bottom. This creates a cleaner overall aesthetic in the control room.

MEET THE FOREMAN

Zach Schreiner has been with Morse Electric for over 11 years and was the Foreman for ZINKPOWER. Zach did an excellent job managing the evolving scope of work that’s associated with a design build project, leading his crew through challenging supply chain issues and harsh conditions to keep work moving forward in order to meet the short schedule. “Thanks to an amazing crew, we were able to shift focus as needed and get the job done. As the project winds down, it’s nice to step back and see the end result of our hard work.”