Building Information Modeling (BIM) is used in architecture, engineering, and construction to generate a digital 3D representation of a building. This digital model contains all the same physical and functional characteristics as the actual building and creates a virtual world for designers to work in before a shovel ever meets the dirt. Designers place all the required building components into the model to ensure they will fit within the designated space, identify any clashes between trades, and ensure constructability in the field. The model will play a large role in scheduling and logistics as the project progresses and will continue to be utilized long after the building is complete.

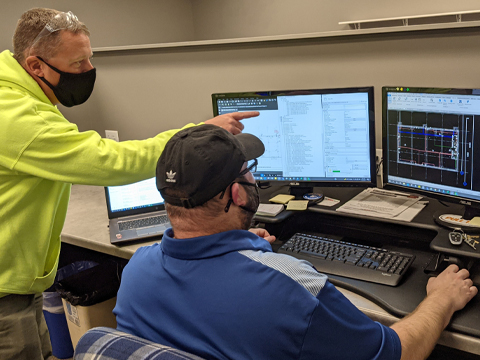

Collaborating on a Project Layout

BUILDING THE MODEL

Before the model can be developed, extensive planning and information gathering must take place to ensure the model is complete and accurate. Information comes from the architectural drawings and the real-world environment where the project will be located. The BIM team collaborates with the Project Foreman to determine the basic layout for gear, panels, and raceway routing. Once complete, the team reviews the layout to ensure constructability.

The basic layout is combined with information from the 1-line diagrams to populate the model with the electrical components. Since every project has specific requirements, submittals play a key role providing detailed information about the exact items being installed during construction. This information is used to create “families”. A family is a grouping of information that provides the distinct size, shape, and characteristics of a component in order to create a virtual “twin” inside the model.

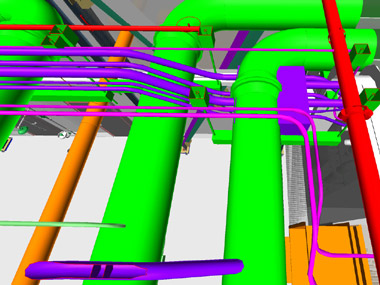

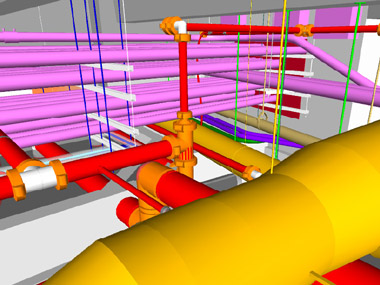

Once the model is completely populated, it undergoes clash detection and coordination. This is a collaborative effort that involves all trades working on the project. The team can easily identify conflicts such as pinch points, trades running into each other, buildability issues, and architectural variances needed for system installation and resolve them before construction.

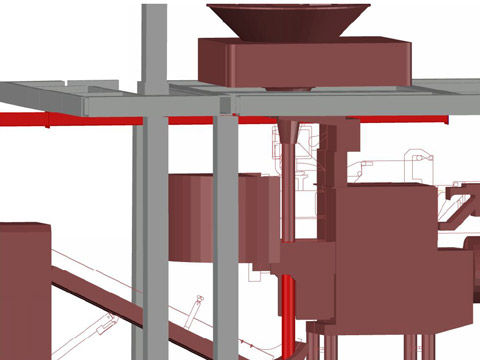

Example of Clashes to be Coordinated in Revit

Project Team Collaborating on a Project Model

Example of a Pinch Point in a Congested Area

FROM VIRTUAL TO REALITY

Once the model is complete and signed-off by all parties it becomes the master plan for construction. A few of the most valuable uses for the model include generating installation drawings, prefabrication, field installation, tracking site progress, and future planning.

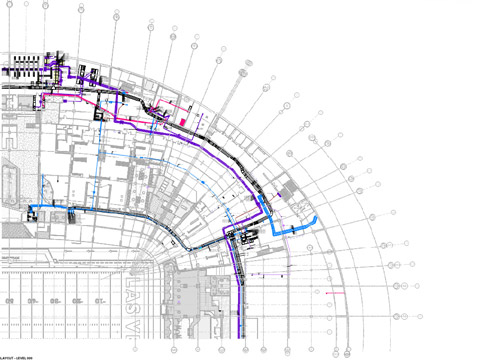

Installation drawings are exported and used for project review, coordination, and installation. This can be done to provide up-to-date drawings for anything from overall floor plans to individual components or enlarge specific areas to show more detail and provide clarity for the installation team.

Installation Drawing Exported from BIM

Utilizing Points from the Model to Layout Conduit Routes

Prefabricating Conduit Bends at the Prefab Shop

Comparing Installation Progress to the Model

BIM utilizes Point Layout software to determine installation points, which allows for the use of robotic survey equipment to mark exact installation locations with a laser. This method saves time on-site and improves accuracy.

The model makes it easy for the BIM team to identify areas that would be practical for prefabrication. Information is extracted from the model and drawings are created for the prefab team to begin assembly.

The model serves as a vital tool in the field. It provides a real-time, accurate reflection of the building. With real-time information at their fingertips, the field can quickly reference the model on a tablet or smartphone to compare installations to the model.

PROJECT COMPLETION AND BEYOND

You might think that once the building is complete, there isn’t any more use for the model. However, if used to its full capacity, it will remain a living breathing entity that is always reflecting the building’s current state. It can be used by operations and maintenance for building upkeep and future renovations. The Morse Group has been successfully incorporating BIM in our projects since 2006. Check out some of our most successful BIM coordinated projects.

Model Indicating Completed work and Future Planning

Allegiant Stadium | Las Vegas, NV

The Morse Group began working on the design-assist phase of the 1.75M sq. ft. sports stadium in 2017 and continued throughout construction. At peak manpower, 600+ crew members and subcontractors were on site. In a project of this complexity, communication and collaboration were paramount for success. During construction, crews utilized Revizto as a mobile BIM software solution. Foremen loaded the model onto iPads and walked the job site. As they moved through the site, the model on screen moved simultaneously allowing them to compare the installation to the model, check for accuracy, and plan for future work.

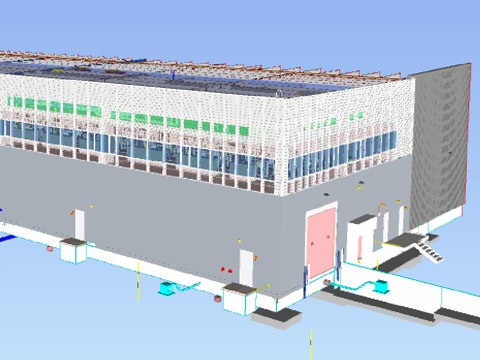

Model of Advanced Manufacturing Facility

Advanced MFG. Facility | Southern WI

The Advanced Mfg. Facility consisted of a 120K sq. ft. Smart Mfg. Center and a 1M sq. ft. Advanced Mfg. Facility. BIM contributed to three key factors that directly resulted in the projects success: material cost reduction, schedule management, and communication/coordination. The model served as a road map for all trade partners and allowed them to coordinate and sequence their work with others to create a seamless flow and achieve maximum productivity. With crews working 6 days a week on two shifts, this was essential to keep work moving forward, avoid work stoppage, and meet the project completion date.

Prefabricated 4×4 Wireway

National Food MFG. Facility | Multiple Locations

The Morse Group designed and prefabricated arms and 4×4 wireways for a national food manufacturer. The objective was to make each piece as “plug and play” as possible. BIM technicians designed the arms and wireways so that most of the wiring would be installed during prefab assembly. When the plant closed for shut down, crews installed the new equipment, ran the remaining wiring and completed the installation in significantly less time than traditional methods. The design reduced downtime so much that the customer has deployed it at multiple sites nationwide.