Malta, IL

R&D Innovation Center Rendering. Photo Credit: Syngentagroup.com

Syngenta’s “farmer-first” R&D Innovation Center in Malta, IL is an 88-acre, five-building campus consisting of a 2-story Customer Experience Center, a Support building (housing electrical rooms, shipping/receiving, and boiler room), a Lab/Office building, a Showroom, and a Well House. The project began June 1, 2022. Morse Electric’s scope of work for this project includes temporary power and lighting, site utilities, site lighting, network lighting controls, fire alarm, and raceway for telecommunications, access control, and CCTV. Crews are on schedule to complete this project in January 2023.

Customer Experience Center Exterior

Second Floor Hall Lighting

CUSTOMER EXPERIENCE CENTER

The Customer Experience Center is designed with areas of open structure, ceiling clouds, and glass curtain walls that open to the outdoors. In addition to a significant amount of glass, the interior boasts metal cladding and wood finished areas. The architecture of the building allows for plenty of direct and indirect natural lighting. The interior lighting package was designed to compliment the natural lighting and consists of 48 different types of fixtures. Morse electricians will continue to install the interior lighting over the next several weeks.

Foreman Tyler Coleman (right) and right-hand man John Pierce (left) in front of the main 4000-amp switchboard

Mark Garlic working on ATS installation

POWERING INNOVATION

The Power Distribution system is comprised of 4000-amp, 480-volt service. Two 750kW CAT paralleling diesel generators, a generator switchboard, and seven ATS’s provide the emergency and backup power for the campus.

Underground Electrical Installation

Boiler Room

Utilizing our Trimble GPS layout tools, our team was able to begin the electrical system installation early in the project. With the help of our electricians, the BIM team created the model and conduit routing was laid out long before any walls are installed. A lot of conduit is located in the underslab which was essential to create space for other trades to complete overhead installations in small, busy spaces like the boiler room.

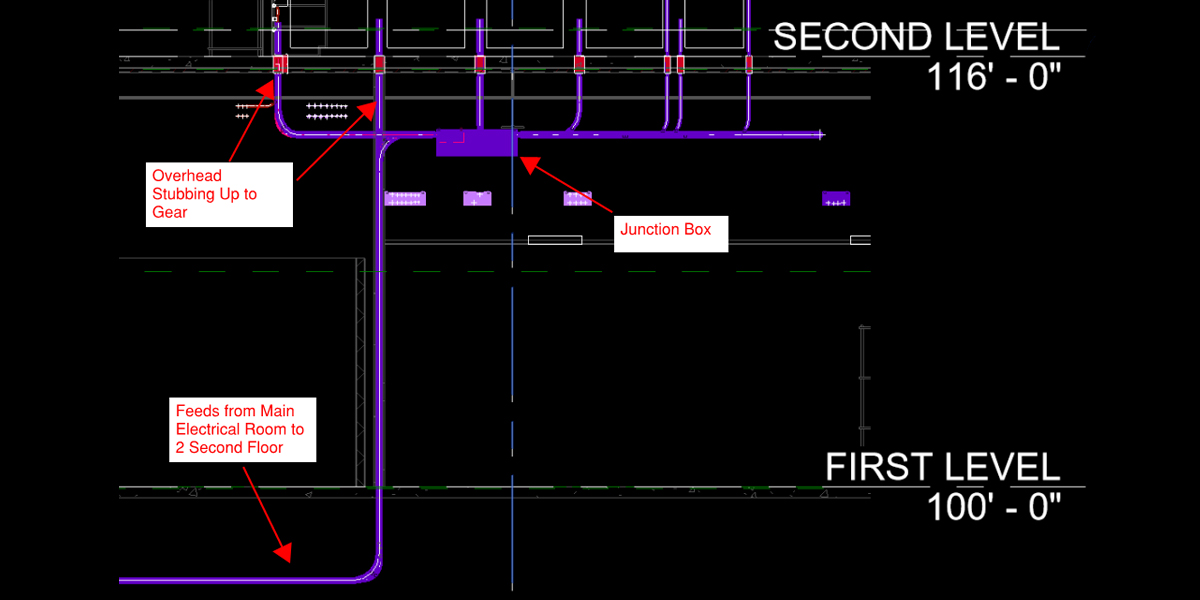

Model of Feeds to Second Floor Stub Up

Foreman Tyler Coleman

MEET THE FOREMAN

Tyler Coleman has been with Morse Electric for over 21 years and is the foreman for Syngenta’s R&D Innovation Center. Over the years, Tyler has been a jack of all trades and has been willing to go anywhere to fill any role needed. As a foreman, Tyler provides clear and concise layout direction to the crew which facilitates a smooth installation.