BELOIT, WI

ABC Supply NSC II was a 3-phase project that kicked off in early 2019 as a Design-Build collaboration with Corporate Contractors, Inc. Construction began in May 2019. Phase One included the 4-story shell, basement level, and build-out of the first and second floors, and was designed to accommodate approximately 300 employees. Although expansion to the third and fourth floors was planned from the start, the building reached full capacity sooner than anticipated. In February 2023, crews returned to complete the build-out of the third floor, adding office space for an additional 150 employees. As the third-floor work was wrapping up, preparations for the fourth floor build-out were already underway. With the completion of the fourth-floor in early 2025, ABC Supply NSC II is fully complete and houses approximately 600 employees.

Morse Electric’s scope of work for this design build project included all the line and low voltage system wiring (data, security, HVAC control, paging system, fire alarm, elevators and lighting control) as well as backup generator, UPS and electric car charging station installations.

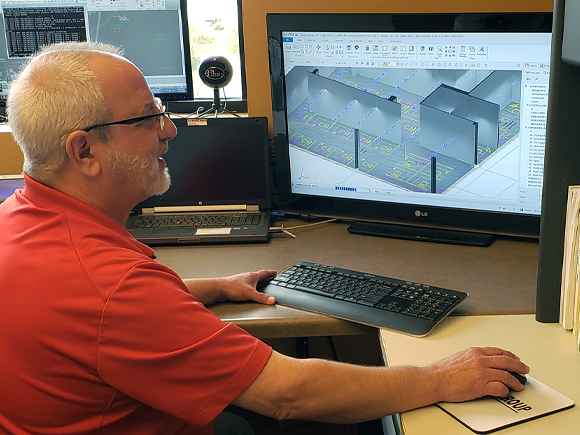

Project Manager Tom Uzun lead the team during the initial Design Build phase of ABC Supply NSC II. Through regular design meetings and one-on-one’s with the Owner & GC, we are able to understand & adapt the design to meet their initial needs & plan ahead for the future. One example of this involved raceways. During the initial build, spare raceways were installed that were used for lighting control and fire alarm additions and changes related to the expansion to the third and fourth floors.

The backup generator chosen for this project is a prime example of planning for future demand. A building of this size, prior to the build-out of the upper floors, would typically require a smaller generator. Instead of opting for a generator that only met immediate needs, Morse Electric proposed a 200 KW diesel backup generator with a 785-gallon fuel tank—enough fuel to keep the entire building running for 48 hours without utility power. Although the initial cost was higher, the larger generator ultimately resulted in long-term cost savings for the owner.

The architectural design for the third and fourth floors of ABC Supply NSC II made for some challenging electrical installations. In order to achieve the cloud ceiling effect, the ceiling shifted between a hard ceiling and a drop ceiling causing Morse Electricians to change installation methods when moving between the two. Many of the offices feature a glass accent wall which posed another challenge for the electrical installation by creating a “no fly zone” for electrical components.

Prefabrication played a large role in all three phases of the ABC Supply NSC II project. Crews utilized prefabricated receptacle boxes, whips, pre-bent data stubs, and rough-in ready data boxes to make quick work of the electrical installation in multiple offices. The team also designed a custom hinged box with receptacles and a protective cover to save even more time. Once the walls were finished, crews simply removed the protective cover and installed a wall plate to complete the installation.

FUN FACTS ABOUT THIS PROJECT

Justin Hesselbacher was the only team member to work on every phase of the ABC Supply NSC II project.

The project team worked in excess of 32,500 manhours completing this project.

Morse Electricians installed 50+ 120V/20A circuits dedicated to powering the window shades.

To minimize disturbance, material for the upper floors entered the building through a window.

MEET THE FOREMAN

Jason Grenawalt was the foreman for Phase One of the ABC Supply NSC II project. Jason enjoys the early phase of construction and developing a plan to lead the team from start to close-out. Jason finds the planning stage of a design build job particularly challenging and rewarding.

Justin Hesselbacher was the foreman for Phase Two and Three of the ABC Supply NSC II project.

The biggest hurdle Justin faced was the expedited schedule. The crew showed great adaptability to changes and flexibility with irregular hours, including third shift and several weeks of 4 a.m. start times, to stay on track with the schedule. Excellent communication with Project Manager Mark Mezera also played a key role in the success of the project.